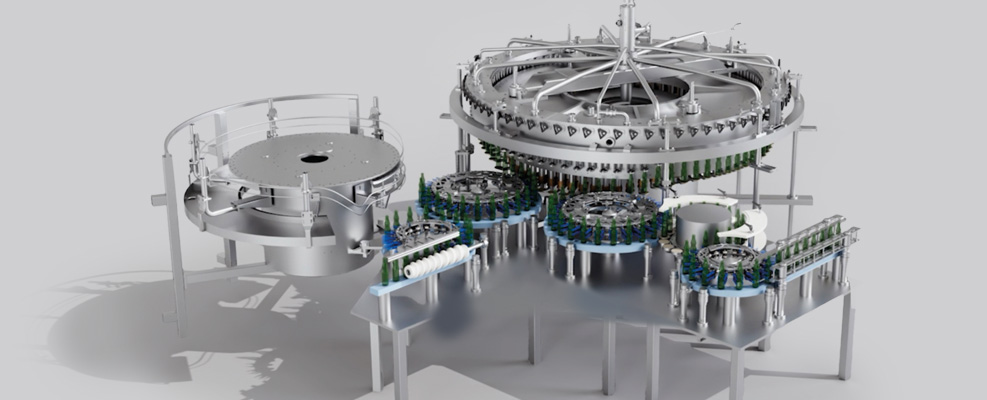

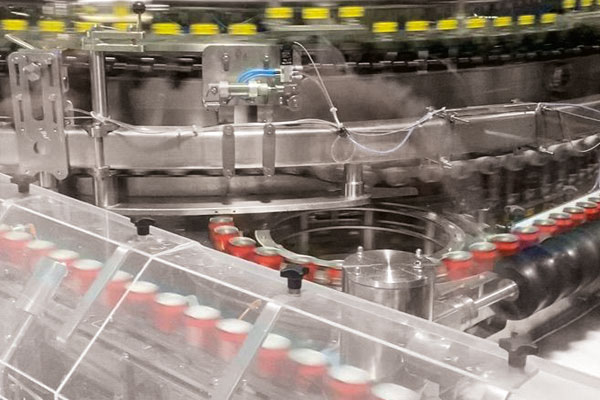

- Audax C is a fully automatic rotary can filler, designed and manufactured for high-speed filling lines suitable for both carbonated and still products.

- Audax can be coupled with it’s rinser and with major suppliers seaming and capping equipment.

- Audax’s base is made of sanitary finishing stainless steel AISI 304 clean design top surface in order to facilitate liquid drenage.

- Audax’s parts in contact with the product are made of stainless steel AISI 316L.

- Audax is protected by tempered glass perimeter safety guards, supported by an AISI 304 frame. Safety is ensured by an interlock system

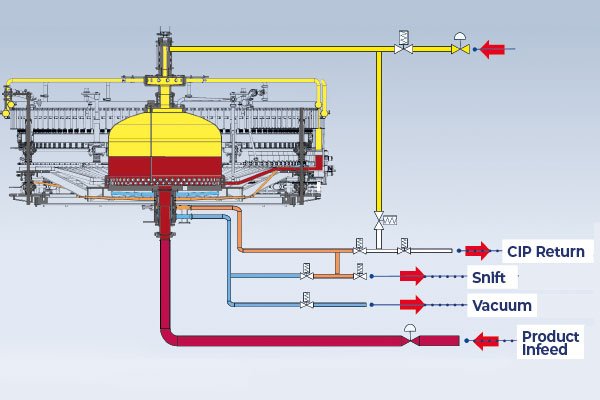

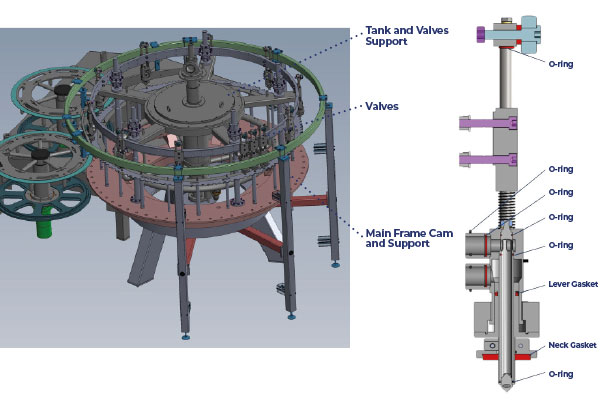

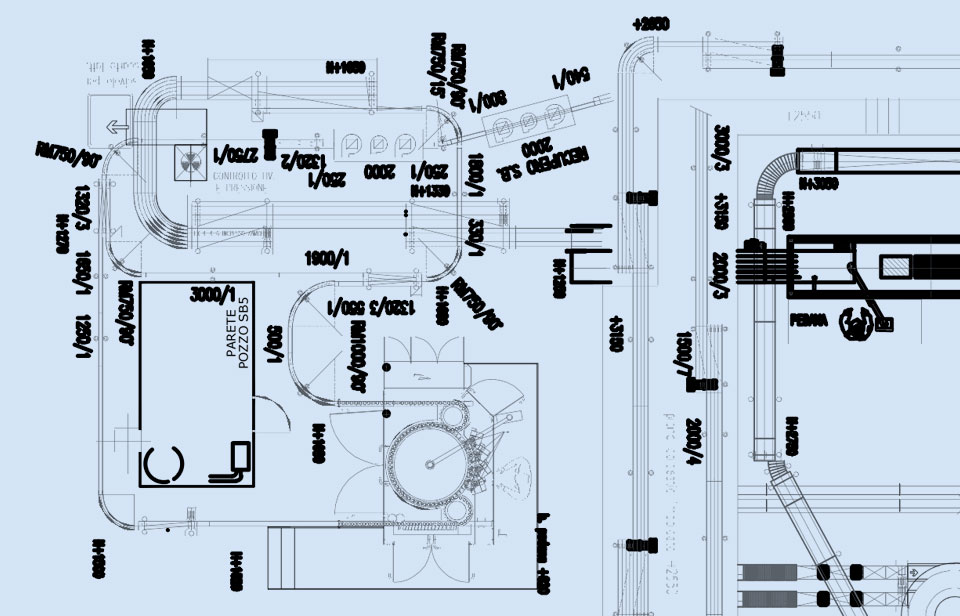

Audax is equipped with a central tank that feeds all filling valves through radial pipes.

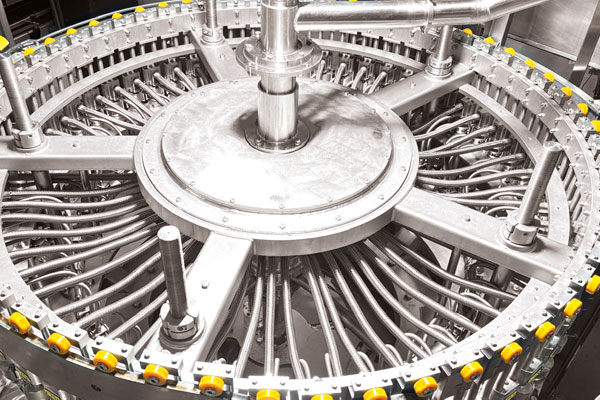

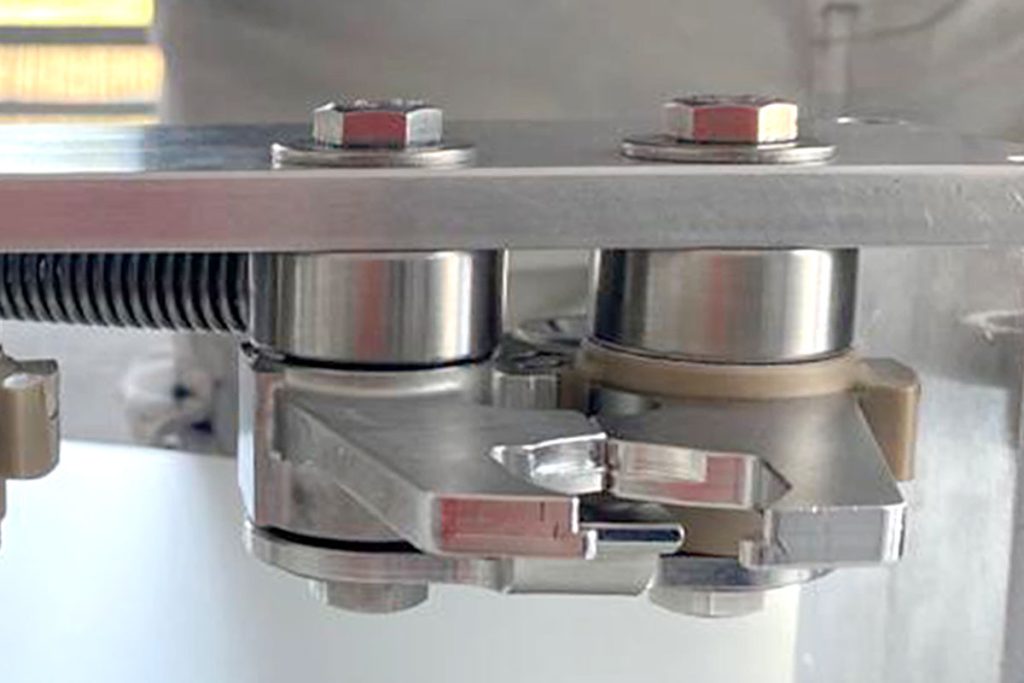

- Audax’s filling valves are equipped with a volumetric dosing system using cylinders with magnetic floats.

- Audax’s carousel features a rotary section supported by a large-diameter main bearing, guaranteeing maximum stability.

- Audax’s product supply enters from the bottom and is conveyed to the central tank, which feeds all filling valves through a system of radial pipes.

- Audax can be optionally equipped with automatic dummy cans or bottles.

- Audax features an automatic height adjustment system, fully controlled from the operator panel, delivering significant time savings during format changeovers.